Production lines in manufacturing companies consist of many devices and machines, both fully automatic and operated by skilled workers. In small production plants, simplified and physical solutions are often used. However, the larger the production hall, the more elaborate the systems - not only for managing production but also for transporting goods between departments and production stages. To move goods of different sizes, shapes, and weights, conveyors, also called industrial transporters, are used. What are these devices? What types can be distinguished? And what are the advantages of their implementation in an enterprise?

The first belt conveyors

The history of belt conveyors begins at the turn of the 18th and 19th centuries. Initially, these machines were simple in terms of the way they were driven and their construction. However, with time and with the development of new technologies and the beginning of the industrial revolution, more and more automated solutions were used, which are now an integral part of many industrial halls. In the early stages of development, they were used for loading goods onto ships, among other things - today they are used in virtually every industry where industrial production takes place.

Read also about the road to Industry 4.0: The road to Industry 4.0

Conveyors - types

Conveyors can be used for short-distance transport in production plants (among others food, cosmetic, automotive, chemical), warehouses, sorting plants, mines, and construction sites. Depending on the shape, weight, and size of goods, as well as the designed technological process, many types of conveyors can be used. In this article, we will present some of them.

Belt conveyors

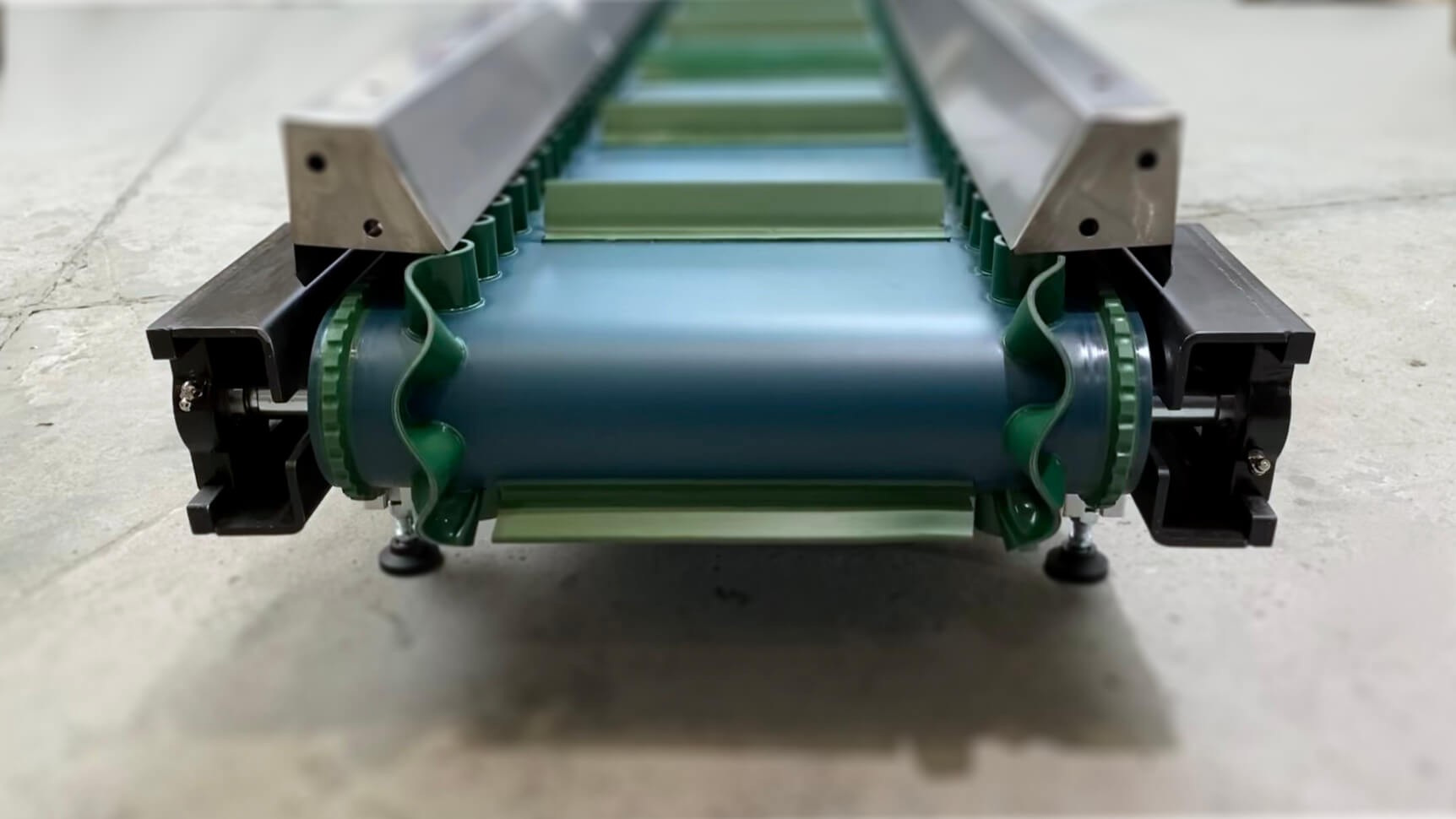

It is one of the most popular types of conveyors. It has a simple structure (horizontal or ascending, usually constructed of aluminum profiles). The element which enables the transport of products is the belt. The conveyor also has a driving drum, which sets the belt in motion, making it possible to move the goods from A to B. Belt conveyors can be implemented independently or in a configuration as a buffer conveyor, which consists of two conveyors working in two different directions.

Belts made of different materials, such as steel mesh, rubber, PVC, or polyurethane, can be used to build this type of conveyor. In conveyors intended for the food industry, belts that are adapted to contact with food are used.

Picture: ATMAT belt conveyors

Picture: ATMAT belt conveyors

Plate conveyors

This type of conveyor is used with products of limited shape and weight such as bottles, jars, cartons, and cans. Plate conveyors are useful in the process of filling, labeling, and closing packages, i.e. on the production line of food products as well as chemicals and cosmetics. Plate conveyors are adapted to the dimensions of the product, and thus they take up less space and shorten the distance between successive stages of the industrial process. It is worth using conveyor plate belts in production environments where the line will operate at high temperatures. They are also ideal in situations where damage is likely to occur - plate conveyors are more durable and resistant.

Chain conveyors

This type of conveyor is used wherever it becomes necessary to transport pallets, baskets, cartons, and products of high weight and dimensions. The sliding elements which are responsible for transporting the products are chains. Chain conveyors are used particularly for pallets.

Industrial conveyors for a custom-made

Individual approaches and tailor-made projects ensure that the ordered industrial solution will be adjusted to the characteristics of the product, production hall space, conditions in it, and the technological process.

ATMAT engineers will consider the optimal solution for industrial conveyors at the design stage. What is more, they will select appropriate components and supplementary devices. We invite you to contact us for a customized offer for ATMAT industrial conveyors..png)

.png)