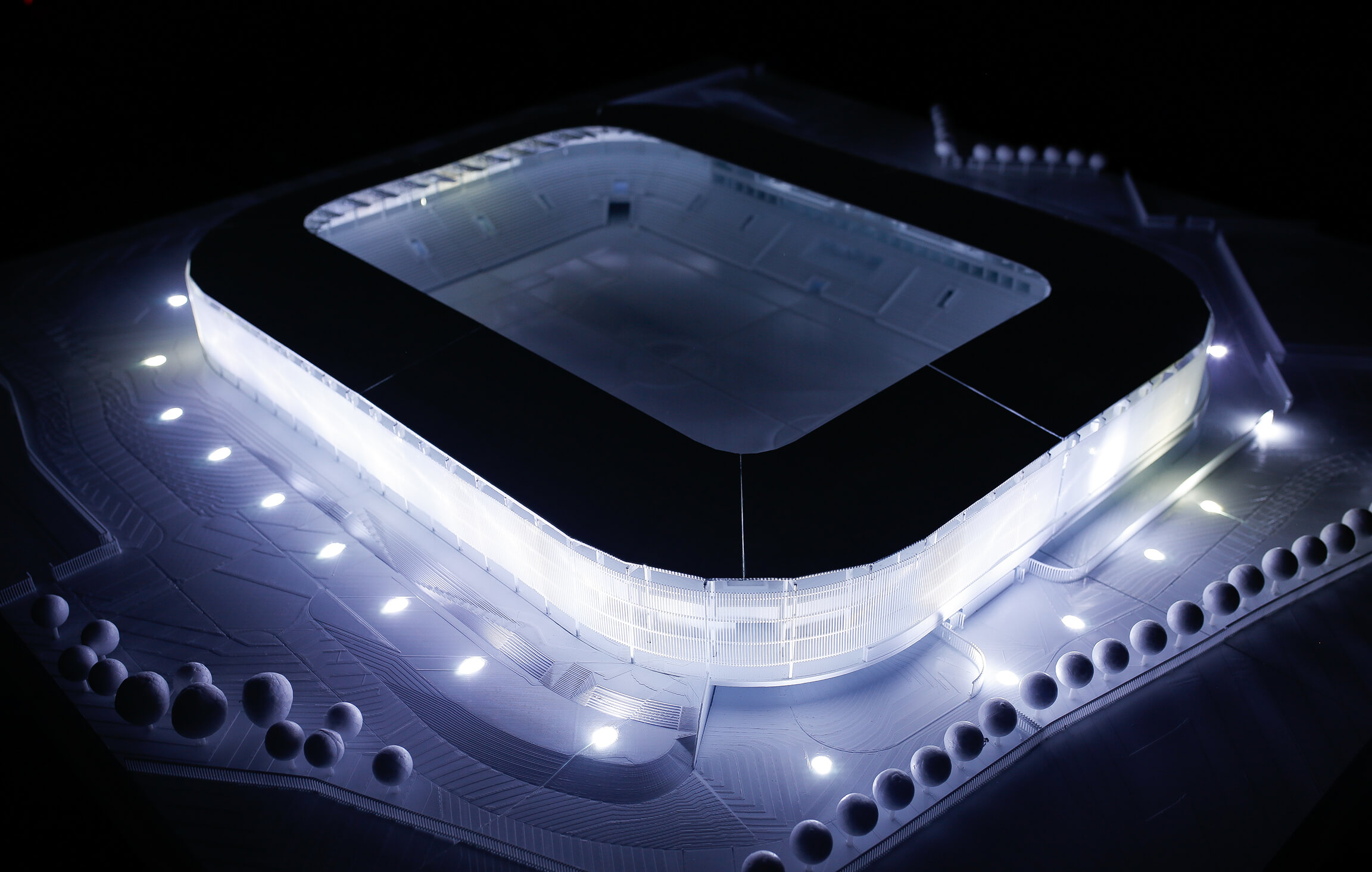

3D printing is successfully used to produce architectural models. The additive manufacturing technology ensures quality, durability, and precision even when precise details are printed. One of our latest realizations is the model of the Kazimierz Górski Stadium in Płock. The mock-up was printed on Signal Pro and Galaxy 3D printers.

3D printing works well in many industries. Its significant advantages can be seen in architecture, e.g. for making mock-ups.

We wrote about it, among others, here: A modern way of presenting the designer's vision

Creating mock-ups manually requires time, specialized tools, and skills. Traditional materials used to make them are cardboard, plastics, gypsum, or wood. These materials, however, are fragile and susceptible to damage. A much more durable and professional method of making mock-ups is additive manufacturing technology made of plastics.

Photo: M.Sc.Eng. the architect Jan Łabowicz

Photo: M.Sc.Eng. the architect Jan Łabowicz

Below we present one of our recent projects made in cooperation with the Studio of Architectural Mock-ups PMA.8.

The mock-up of Kazimierz Górski Stadium in Płock. Wisła Płock with dimensions 114 x 114 x 20 cm was printed in parts on the ATMAT Signal Pro and Galaxy 3D printers.

- Printing time: ~563h,

- Material: PLA

- Scale: 1:250

- Technology - druk 3D FDM/FFF

- Lighting: USB LED 5V

The model is dividing in two parts along a longitudinal section through the center of the stadium.

The author of this project and the photographs is M.Sc. Eng. the architect Jan Łabowicz,

Pracownia Makiet Architektonicznych PMA.8,

Phone: 600-877-810

https://www.facebook.com/Yteikam.makietY