Students are extremely creative people, for whom the word "impossible" does not exist. Looking at the achievements of young engineers forming the joint project E-MOTO AGH, it is difficult for us to disagree with this statement.

A group of automotive enthusiasts - and at the same time students of the AGH University of Science and Technology in Krakow - decided to join forces and construct an off-road electric motorcycle powered by alternative energy sources. This is one of the first vehicles of this type in Poland, and we had the pleasure to participate in its creation.

To test the possibilities of the motorcycle, students took part in the SmartMoto Challenge 2017 competition in Barcelona, where the bike presented itself at the highest level and enabled the group to get first place in three categories and fourth in the general classification. The E-MOTO AGH team also received the title of the best-performing new team during the competition. So far, students have built 2 motorcycles, which they are planning to improve in the 2018/19 season.

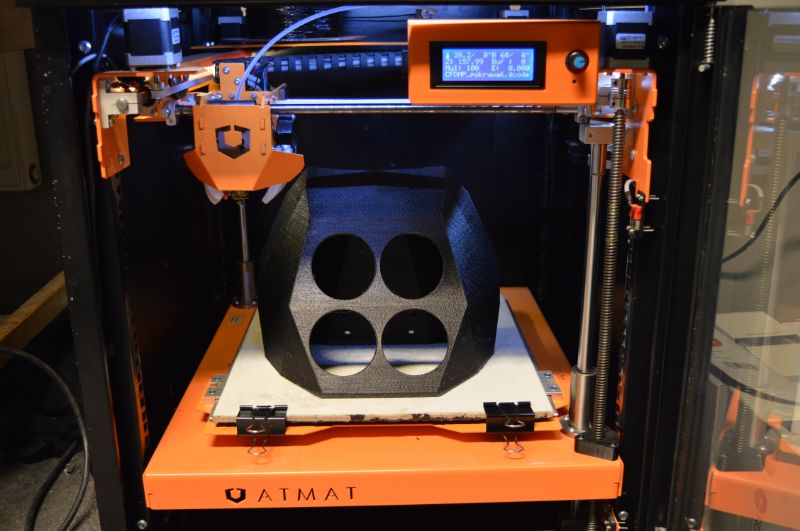

To get individual components of the bike, students used one of our pioneering 3D printers - ATMAT SIGNAL, which combines a simple device structure with great print precision and high efficiency. Using this printer allowed them to print items such as the front of the motorcycle head (front hood), chain cover, fenders or a seat frame. Of course, at the time of using the equipment, our cooperation does not end - we are happy to share our specialist knowledge with the students, carry out the necessary introductory training and support them at every stage of production.

An individually designed and folded motorcycle is a unique product, which is why the fastest and cheapest way to obtain specific components for it is to print them in a 3D printer. One of the biggest advantages of this method is the possibility of rapid prototyping and repeating the printout with the changes. Such an unusual element in the construction of an electric motorcycle, are battery baskets that have been repeatedly analyzed and changed, in the final project they take up little space, they hold all the batteries in a proper distance and at the same time are durable and safe.

.jpg)

Members of the E-MOTO AGH prove that 3D printing is the future of the automotive industry. Many entrepreneurs are slowly realizing how big the potential of spatial printing is not only to create prototypes but also to produce specific parts or - in the future - even entire devices. This technique enables low-budget unit production. Thanks to this, we can modify projects in response to changing technological and design trends.