Choosing the 3D printer, users primarily pay attention to technical parameters of the equipment, print quality and precision. However, in the era of intensive technology development and ubiquitous access to smartphones, tablets and laptops, the possibility of user communication with the device, intuitiveness of use and quick access to desired information are also of increasing value.

By using a modern application designed to support ATMAT Signal Pro and ATMAT Galaxy printers, production processes will be streamlined and optimized, and the use of 3D printers will become even easier.

One of the most important functions of the application is the option to send the print design using a LAN network connection with the printer - it is an excellent tool that speeds up and streamlines the start of the printing process. W razie potrzeby projekty mogą zostać zapisane w pamięci wewnętrznej urządzenia, co jest przydatne zwłaszcza przy drukowaniu powtarzalnych projektów.

What changes can we expect?

The very first functionality that is visible immediately after starting to use the 3D printer is a quick access bar with grouped application options, presented in a graphic form, located on the left side of the screen. This seemingly small change enables more efficient use of the equipment and allows you to maintain smoothness and speed of work. A larger screen and easy-to-use interface are another advantages.

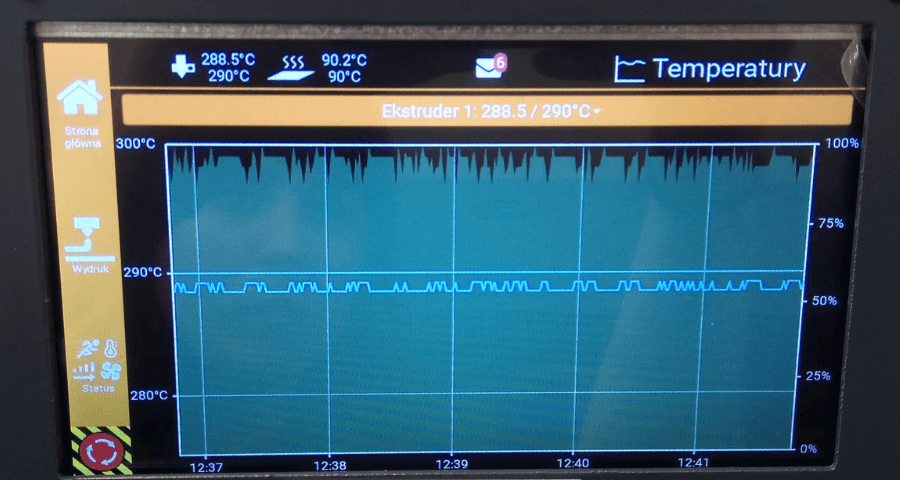

The application also allows you to view live parameters such as:

- printing speed,

- print temperature,

- temperature inside the device,

- filament flow,

- degree of heating of the printer.

At every stage of printing, we can verify the work progress of the printer (on a scale of 1 to 100%) as well as the amount of time left to finish the printing process (with an accuracy of 1 minute). Thanks to that, users can plan the rest of the tasks at ease and organise their work time better, thus increasing the effectiveness. Access to information on filament extraction paths enables an accurate analysis of 3D printers work, and in the area of creating available connections and constant improvement of projects in the future. Using the application, we can also fine-tune the calibration thanks to a built-in function of micro-step, which is especially important when printing using very small nozzles.

Users often using demanding filaments - such as nylon or ABS - will certainly appreciate access to equipment statistics in which they will be able to analyze e.g. temperature fluctuations affecting the quality of the product obtained.

In case of any anomalies during the printing process, we are informed immediately – thanks to the notification function. It allows for saving materials and user time, increases printer performance efficiency and gives you the ability to react quickly. The application also enables usage of the security button and stopping the connection from the interface level - until now it was only available through a special button located on the printer housing.

Remote work? Now it is possible!

All actions, including starting the printing process or printer heating, can from now on be made remotely - from the computer level. Thanks to the application, in models with a camera mounted inside the device, we get the access to life preview of the print, and thus even in an office located in a considerable distance from production hall, we will be up to date with work progress.

The application has been perfectly refined in terms of functionality - it increases the efficiency of printers equipped with it and facilitates the user's communication with the device. It is worth finding out about it on your projects.