Filaments are materials used to create 3D prints that differ from each other in chemical and physical properties. Depending on individual projects and objects, we use different types of filaments. We always choose the highest quality materials, as the success of the print largely largely on them. One of the factors to consider when choosing the right filament is the Shore scale, which determines the hardness of materials on a scale of 0 to 100 - the lower the value, the greater the elasticity of the material.

Despite the wide range of filaments available on the Polish market, the most popular are ABS, PLA, PETG and nylon.

What should you know about the filaments?

ABS

Acrylonitrile Butadiene Styrene (ABS) is a material with a wide range of applications and high durability while having a relatively low production cost. Flexible ABS material is perfect for printing moving parts, research models or mockups and film props. Since it is resistant to corrosive chemicals, it can also be used to print pipes and other components used in the chemical industry.

An important feature of this filament is its large contraction during printing. To overcome this feature, a high production temperature (240-260 ° C) and a heated work table (80-110 ° C) are used. At ATMAT, to ensure the highest print quality, we use 3D printers with a built-in working chamber that maintains a relatively constant and high temperature. These are models such as ATMAT Signal, Signal Pro, Galaxy, Saturn and Jupiter.

Because ABS is an artificial polymer, it emits unpleasant, harmful to people fumes during 3D printing. If you decide to print out of this material, you should ensure adequate ventilation of the room where the printing will take place.

The characteristics of ABS are:

- High strength and elasticity of the material.

- Hard but easy to process.

- Suitable for grinding and polishing, it is soluble in acetone (smoothing the material).

- Problematic when printing - high material shrinkage.

- Used in the industry (also in chemical one), for printing moving parts, mock-ups, research models, exoskeletons, ergonomic elements.

PLA

The second most popular filament used for printing in FFF technology. It is made out of natural ingredients such as corn starch and sugar cane.

PLA is an ideal filament for beginners - especially suitable for printing figurines, car gadgets or small accessories, while in use of professionals, among others for printing dentures and functional prototypes, also in large sizes.

PLA is less demanding than ABS - the melting point during printing is lower, it does not emit such harmful fumes and is not a highly shrinking material. In addition, PLA is a visually attractive filament because of its smooth and shiny texture and intensely saturated colours. However, this material is not perfect. It has less elasticity than ABS (which is why it may crack during printing) and the possibility of deformation under the influence of high temperatures.

.jpg) Printout from PLA

Printout from PLA

The characteristics of PLA are:

- Good strength, small material shrinkage (no need for a heated table usage).

- Limited flexibility, the possibility of cracking and deformation under the influence of high

- temperature.

- Visually attractive material, available in many colours.

- Used to make functional prototypes, figurines, film gadgets, game accessories, dentures, demonstration prints and large models.

PET-G

The PET-G filament was made for the needs of 3D printing from polyethene terephthalate with glycerol admixture. Its main advantage is high material durability and flexibility, while the characteristic feature is transparency (except for white, black and orange). The filament is also distinguished by very good adhesion of subsequent layers during printing and low shrinkage of the material - however, use of a heated table is required. Most of the ATMAT 3D printers have this functionality, so you don't have to worry about the printouts peeling off during the printing process.

The PET-G material has a wide spectrum of applications - it is used to print handles, load-bearing elements and elements resistant to grease, gasoline and oils. After receiving the appropriate certificates, it can come into contact with food - as e.g. bottles, jars or storage containers.

The characteristics of PET-G are:

- Greater strength than ABS and PLA, high flexibility.

- No noxious vapours are released during printing.

- Used for printing load-bearing elements, resistant to grease, gasoline, oils, for the production of Christmas decorations, blister packs, lamp covers, bottles, jars.

Nylon

Nylon is a polyamide material, distinguished by high durability, strength and extensibility. ATMAT uses two variants of nylon: PA 12 and PA 6/66.

PA 12 is characterized by high fatigue strength, good dielectric properties, dimensional stability and low moisture absorption.

PA 6/66 is characterized by high heat resistance, mechanical durability and hardness.

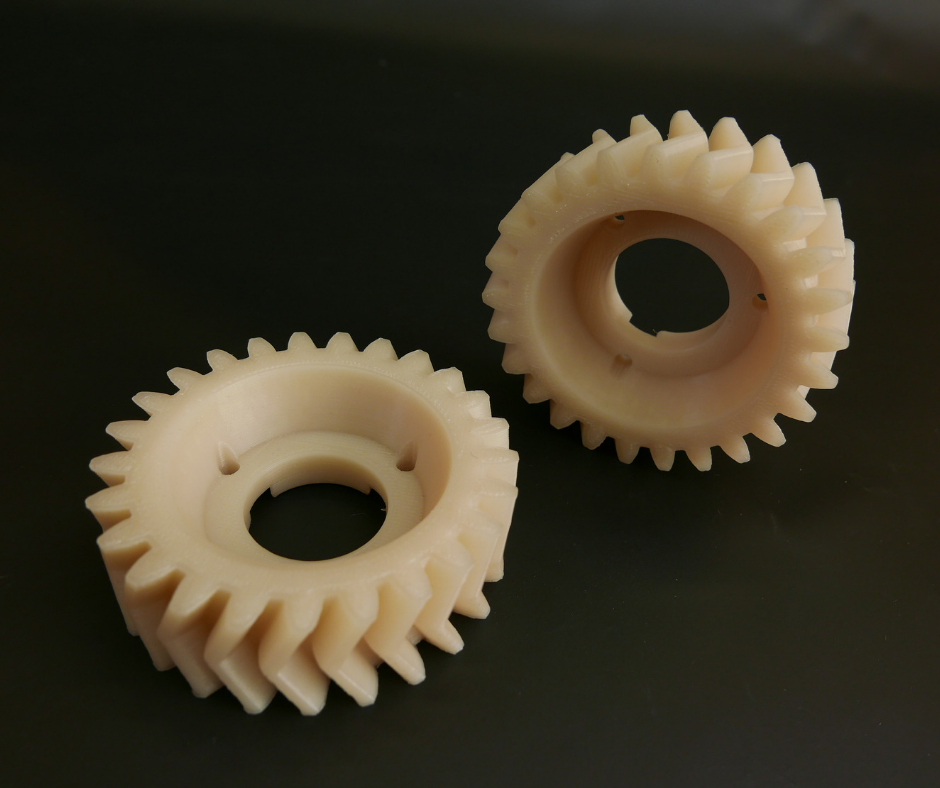

Nylon is a difficult, but extremely attractive material - the printouts obtained from it are light, durable and precisely finished. Ideally suited to printing elements used in the transport, electrotechnical, automotive and machine industries - i.e. those that must withstand high mechanical loads. This filament is intended for use only by professionals who are able to skillfully adjust the print parameters to obtain the highest quality products.

.png)

Nylon printing with the addition of carbon fibre

The characteristics of nylon are:

- Very durable and resistant to heavy loads, abrasion-resistant.

- Light, perfectly finished, insoluble.

- Emits noxious vapours during printing.

- Used for printing in the transport, automotive and machine construction industries.

Printout from nylon

Printout from nylon