Some students print components for a solar boat, some print components for an off-road motorcycle, while students from Ostrava print components for an electric car in 3D.

StudentCar is a Czech scientific program in which students learn how to construct car prototypes. They make their concepts and mechanical designs, test the strength of parts and produce individual components to finally assemble the vehicle and perform the test drive themselves. Their new project is the electric car Buggy, equipped with parts printed in 3D printing technology.

Buggy car, Design and implementation - StudentCar

Buggy car, Design and implementation - StudentCar

Students from Ostrava used to work on standard 3D machines. When printing large elements - such as the dashboard or the bumper -they had to divide the printing components into a pair of parts and then complete the printing. Looking for new possibilities, they found a solution to print the elements in their full size - the ATMAT Jupiter printer.

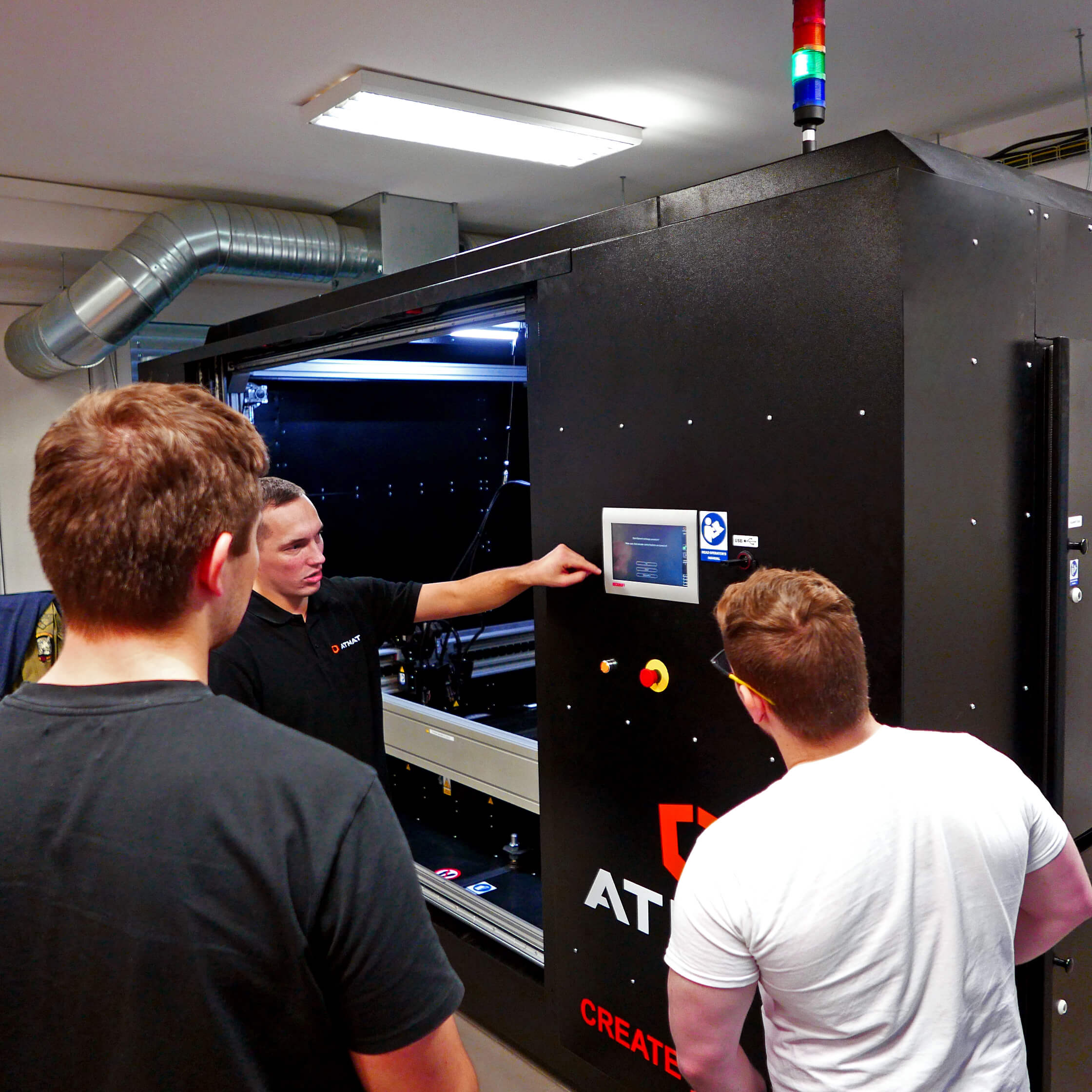

The implementation training conducted by ATMAT Engineers

The implementation training conducted by ATMAT Engineers

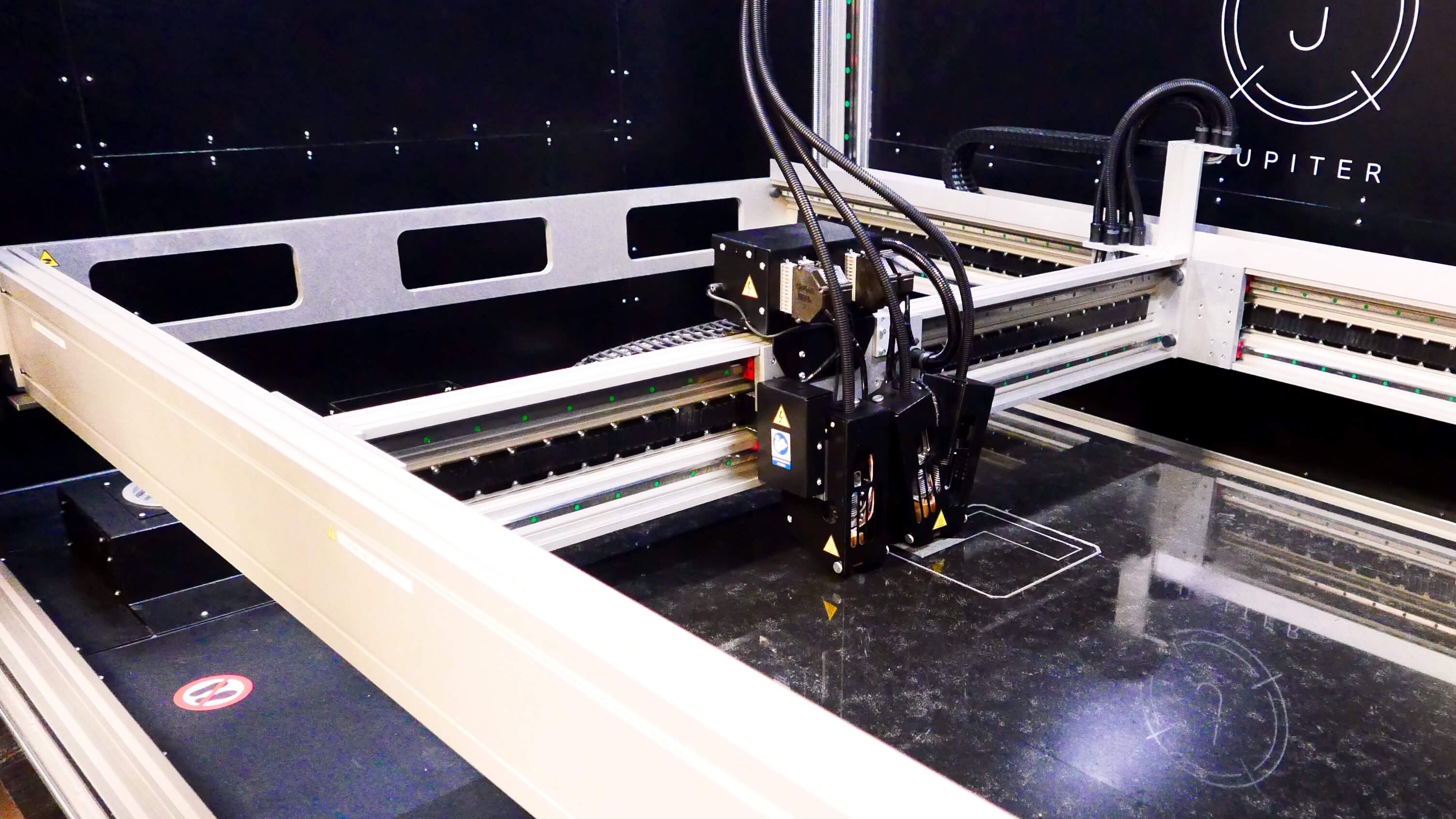

The Jupiter large format printer is one of the largest industrial grade machines in Europe. It' s workspace allows it to print models up to 2 meters long - so it is excellent for the automotive industry.

Working area of the JUPITER large scale 3D printer

Working area of the JUPITER large scale 3D printer

3D printing in the automotive industry is growing in popularity - corporations use it to produce engine components and various systems, prototype car parts and produce spare parts. The application of 3D printing technology in the automotive industry helps to reduce the costs of production and storage of parts and to speed up the production time of individual components.

JUPITER large-scale 3D printer

JUPITER large-scale 3D printer

Students from the StudentCar project completed an implementation training, during which they learned the specification of the Jupiter printer. Parts printed on standard 3D printers will be progressively replaced with the parts printed entirely on the large size Jupiter printer.

We will keep you updated on the progress of the project.