Signal Pro

Continuous widening of perspectives

The Signal Pro series of 3D printers is created in response to the expectations of our customers - people looking for fully professional solutions and demanding very high quality. The possibility to choose the size of the working area allows them to perfectly fit into their individual needs. Signal Pro is a model built for both people starting their adventure with 3D printing as well as for those who work in FFF technology every day.

Available working areas

Choose the model that's right for your business

Signal Pro 300

X:300 Y:300 Z:300 mm

Signal Pro 500

X:300 Y:300 Z:500 mm

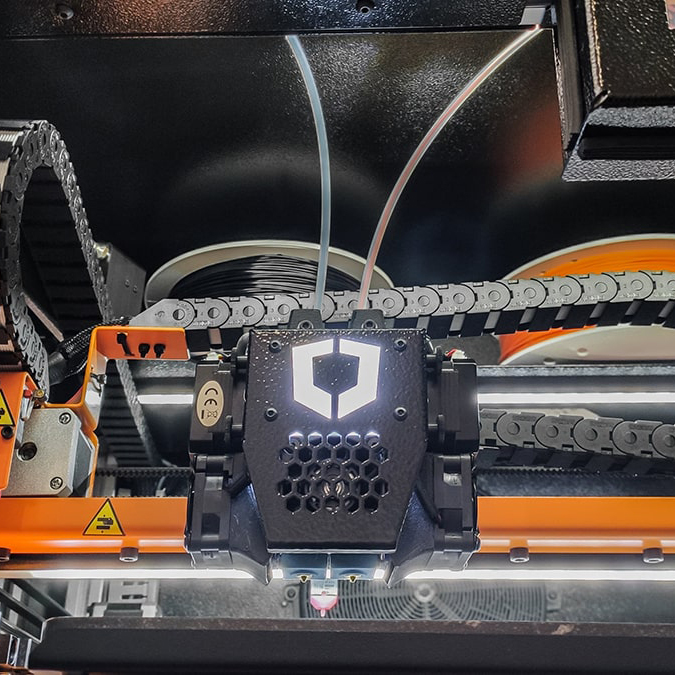

The printhead with a double extruder

The ATMAT Signal Pro device has been equipped with a printhead with a double extruder. This solution allows to print elements in two colors, as well as print using two different materials, including support ones. The choice of materials from a wide range of filaments available on the market provides practically unlimited production possibilities, even complex models. The use of soluble materials such as PVA or HIPS guarantees precise performance of difficult shapes, and then easy removal of unnecessary supports after printing.

Wireless communication

The process of transferring files to the printer, starting printing and controlling parameters can be done wirelessly or using external memory. The use of the built-in WiFi module allows the user to manage printing process from the computer. It is also possible to have a look at the printout thanks to instal camera with a wide-angle lens, installed in the printer chamber. It is a convenient and useful solution, especially in large plants, where it is required to coordinate the work of many printers at the same time.

Active temperature control

The Signal PRO ATMAT 3D printer has been equipped with airtight aluminum construction and a heating control system. This allows to maintain a constant, optimal temperature inside the working chamber. The warm airflow control system used in the housing guarantees the proper working environment for demanding materials, which leads to preventing delamination of the layers and easier tear-off of the printout from the bed surface.

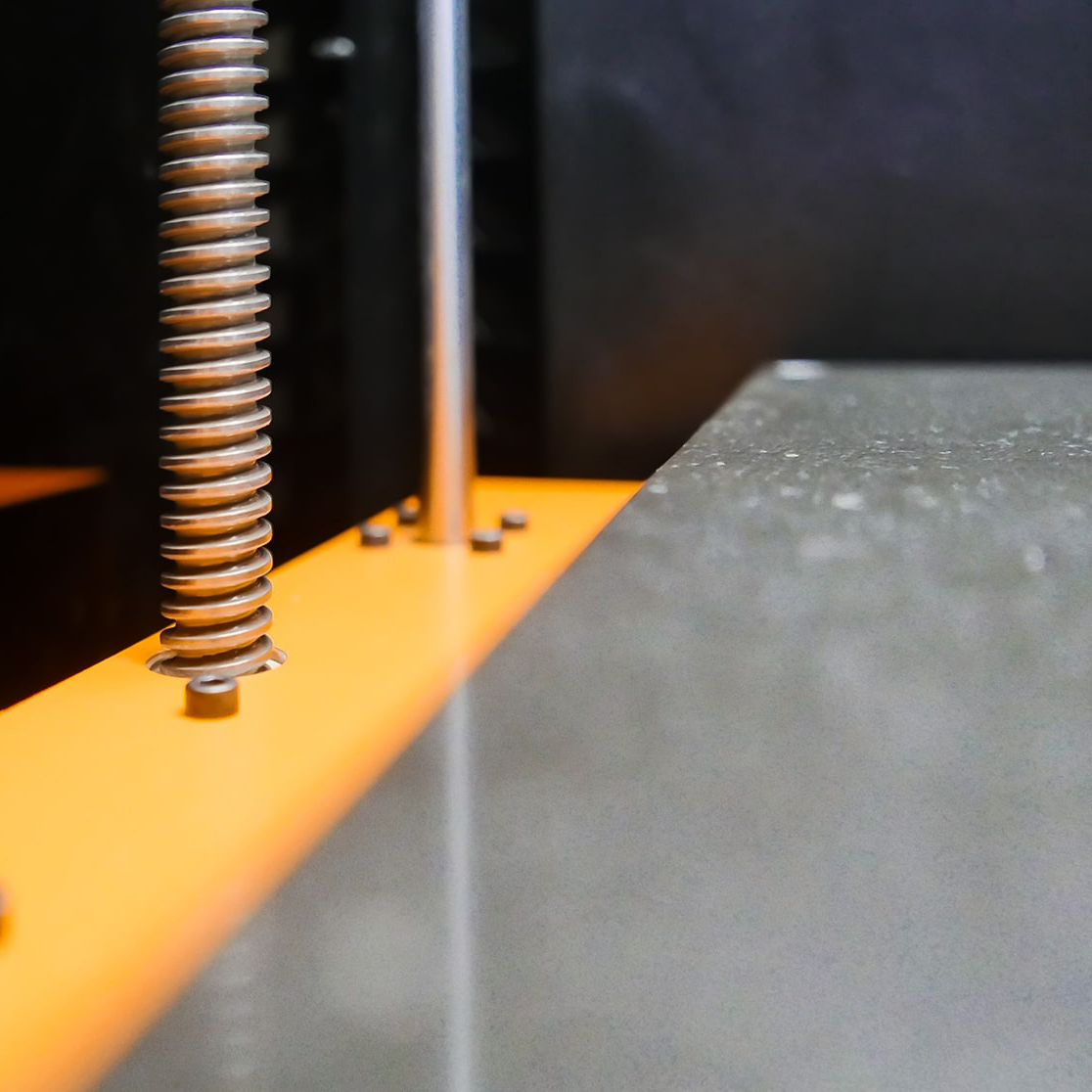

Bed autolevellig

The automatic bed levelling function makes the device work reliably and independently starting from the first layers. Before launching the printing process, the printhead calibrates its position relatively to the distance from the surface of the working table. The operation is repeated in several points oriented on different parts of the working area, so that the distance of the nozzle from the surface is equal in every place. Thus, the risk of incorrect adhesion of the printout and uneven overlapping of layers during operation is eliminated. Autocalibration in combination with the flat granite surface of the working platform guarantees a high level of quality of the printed elements from the very first layers.

High level of safety

Thanks to the safety measures in accordance with health and safety requirements, the printer is adapted to work in offices and production plants. The printhead has a lighting system, where corresponding colors informs the user about current status of the printer such as readiness to work or warming up. All dangerous elements of the structure has been marked with special sticks. The printer has also safety button that allow to stop the operation immediately.

Modernity and functionality

When creating the ATMAT Signal Pro 3D printer, the goal was to provide functionality and modernity, adapted to both everyday and industrial use. The housing of the device is made of aluminum sheet, which meets not only aesthetic values, but also ensures long and trouble-free operation. Professional and high quality components used to build the machine guarantee that the ATMAT Signal Pro printer is solid and at the same time extremely precise.

Discover a new perspective of creation

| Technical specification | ||

| Printing technology | FFF (FDM) | |

| Specification of printers | Working area | X: 300 Y:300 Z:300/400/500 mm |

| Housing | Stable, enclosed, aluminum sheet construction. Lockable door. Space for materials inside the working chamber. | |

| Printing environment | Closed working chamber with temperature control and carbon filter | |

| Max. chamber temperature | 45°C | |

| Working bed | Bed autolevelling, heated working platform | |

| Working bed material | Granite | |

| Maximum bed temperature | 140°C | |

| Head | Nozzle diameter |

0.4 mm (basic), Applicability: 0.25 mm; 0.30 mm; 0.35 mm; 0.60 mm; 0.80 mm |

| Number of extruders | 2 | |

| Extruder type | Direct | |

| Maximum head temperature | 290°C | |

| Parameters of printing process | Layer height | 0.1 – 0.6 mm |

| Nominal printing speed | 150 mm/s | |

| HQ printing speed | 80 mm /s | |

| Maximum passage speed | 200 mm/s | |

| Positioning accuracy of the X/Y axes | 7 µm | |

| Positioning accuracy of the Z axis | 1.25 µm | |

| Software | Cura | |

| File extensions supported by software | .stl, .obj | |

| Filament | Materials |

PLA, PET-G, ABS, TPU, PC, PA, ESD Supporting filaments: HIPS, PVA |

| Material diameter | 1.75 mm | |

| Filament form | Spool | |

| Supported spool weights |

2 x 0.85kg/1.0kg 1 x 2.5kg |

|

| 3D printer operation | Communication | WiFi, LAN (router connection), USB stick |

| File extensions supported by software | .gcode | |

| Control | Touch screen | |

| Remote preview | Yes – a camera with wide-angle lens | |

| Working environment temperature | 15 - 25°C | |

| General data | Power | 230V/50Hz |

| Max. power consumption | 1200 W | |

| Average power consumption in operation for PLA | 250 W | |

| External dimensions |

640x640x850/950/1050 mm (width x depth x height) |

|

| Weight | 55/60/65 kg |

Set of components

Signal Pro 3D printer

Exploitation kit

Two reels of the filament

Technical documentation